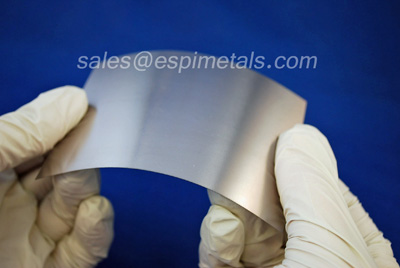

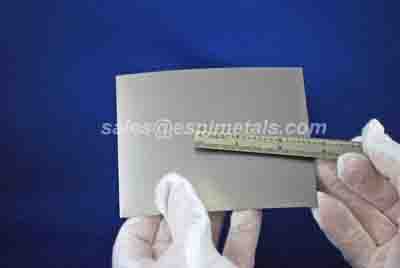

Tantalum Foil and Sheet

|

|

| TANTALUM FOIL | TANTALUM SHEET |

TANTALUM - HISTORY AND USES

Originally known as tantalium, Tantalum (Ta) is an element with the atomic number 73. It’s name is derived from Tantalus, of Greek mythology. Tantalus was punished by the gods and condemned to stand neck deep in water with perfect fruit growing above his head, both of which eternally tantalized him. When he bent to try to drink the water, it drained below his reach, and if he reached for the fruit, the branches moved away from his grasp. Anders Ekeberg, a Swedish chemist who discovered Tantalum in 1802 found that tantalum oxide was insoluble in acid, which led him to name it after the Greek mythological character as "the oxide of this metal was incapable of feeding itself even in the middle of a surplus of acid."

In 1801, Charles Hatchett had discovered a new element which he named columbium when he analyzed a mineral sample called columbite from a collection at the British Museum. In 1809, an English chemist, William Wollaston, compared the oxides derived from both columbite and tantalite and concluded the two oxides were identical, despite their difference in measured density. He decided to preserve the name tantalum. In 1846, a German chemist, Heinrich Rose, argued that there was an additional element occurring with tantalum, and he named it niobium after Niobe, the daughter of Tantalus. Later it was established that niobium was identical to the columbium already discovered in 1801 by Hatchett.

Tantalum is a hard, blue-gray, lustrous metal that is quite rare and is now fabricated rather easily. It has characteristics that include efficient conductivity of heat and electricity, is highly resistant to corrosion and possesses a high melting point of 3017 °C (boiling point 5458 °C, which is only surpassed by rhenium, tungsten and osmium for metals, along with carbon). Hydrofluoric acid can be used to dissolve Tantalum. Tantalum ores often contain significant amounts of niobium, itself a highly valuable element, so both metals are extracted to be sold.

Australia produces the most Tantalum, with other countries such as Ethiopia, China and Mozambique producing a significant percentage of the world's output. Malaysia and Thailand also produce Tantalum as a by-product of their tin mining industry. Future sources of the supply of tantalum are being explored in countries like Greenland, Saudi Arabia, Canada, Egypt, the U.S. and Brazil.

Tantalum is part of the refractory metals group, which are widely used as minor components in alloys. The chemical inertness of tantalum makes it a valuable substance for laboratory equipment and a substitute for platinum, but its main use today is in tantalum capacitors in electronic equipment such as mobile phones, DVD players, video game systems and computers.

TANTALUM APPLICATIONS

The major use for tantalum is in the production of electronic components, mainly capacitors and some high-power resistors. Tantalum electrolytic capacitors exploit the tendency of tantalum to form a protective oxide surface layer; sintered anode tantalum capacitors use tantalum powder, pressed into a pellet shape, as one "plate" of the capacitor, the oxide as the dielectric, and an electrolytic solution or conductive solid as the other "plate". Because the dielectric layer can be very thin (thinner than the similar layer in, for instance, foil of an aluminum electrolytic capacitor), a high capacitance can be achieved in a small volume. Because of the size and weight advantages, tantalum capacitors are attractive for cell phones, computers, and automotive electronics.

Due to its high melting point and oxidation resistance tantalum is used in the production of insulation barriers in vacuum furnaces.

Since it resists attack by body fluids and is nonirritating, tantalum is widely used in making surgical instruments and implants. For example, porous tantalum coatings are used in the construction of orthopedic implants due to tantalum's ability to form a direct bond to hard tissue.

ADDITIONAL INFORMATION ON AVAILABLE TANTALUM PRODUCTS AND FORMS

ESPI provides high purity foil and sheet in many different elements for distribution to universities, research labs and manufacturing companies in numerous purities and form factors (i.e., wire, rod, ribbon, pellets, powder, sputtering targets, discs and custom fabricated parts). We are able to fabricate many of the above to your specification. For form overviews on wire and rod manufacturing or additional detailed information on ESPI's other production offerings, click here.

CONTACT AND ORDERING:

541.488.8311 telephone

800.638.2581 toll-free

541.488.8313 fax

800.488.0060 toll-free fax

This email address is being protected from spambots. You need JavaScript enabled to view it.

GENERAL PROPERTIES

|

Symbol: |

Ta |

|

Atomic Number: |

73 |

|

Atomic Weight: |

180.9479 |

|

Density: |

16.654 gm/cc |

|

Melting Point: |

2996 oC |

|

Boiling Point: |

5425 oC |

|

Thermal Conductivity: |

0.575 W/cm/K @ 298.2 K |

|

Electrical Resistivity: |

12.45 microhm-cm @ 0 oC |

|

Electronegativity: |

1.5 Paulings |

|

Specific Heat: |

0.0334 Cal/g/K @ 25 oC |

|

Heat of Vaporization: |

180 K-Cal/gm atom at 5425 oC |

|

Heat of Fusion: |

7.5 Cal/gm mole |

|

|

ALLOYS

ALLOYS